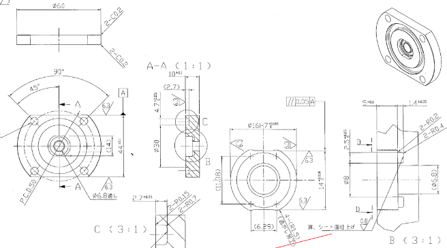

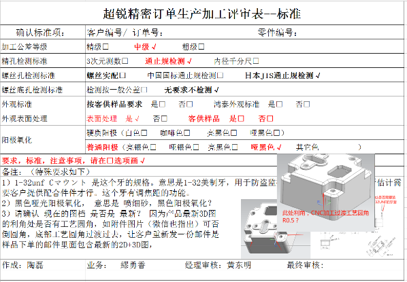

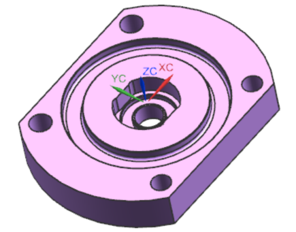

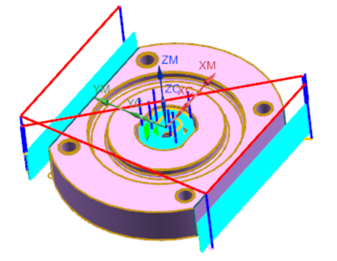

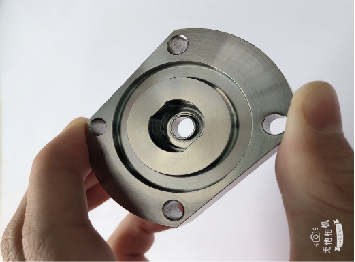

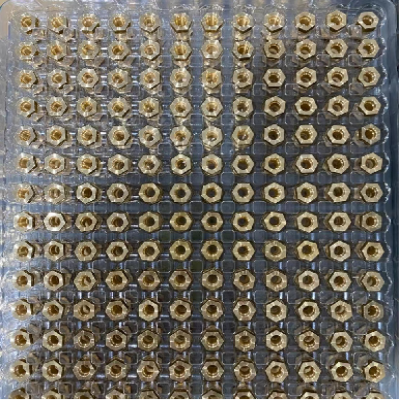

Parts processing,lathe processing

東莞朝宇精密技術有限公司

+86 0769-81667180

24/7 顧客サポート

☆中華街工場で世界をつなぐ

[email protected]

お問い合わせにはいつでも対応いたします

☆御社のパートナーを目指します

機械加工

サービス

Technical Description

利用可能な材料

工場生産能力

適用表面処理

利用可能な材料

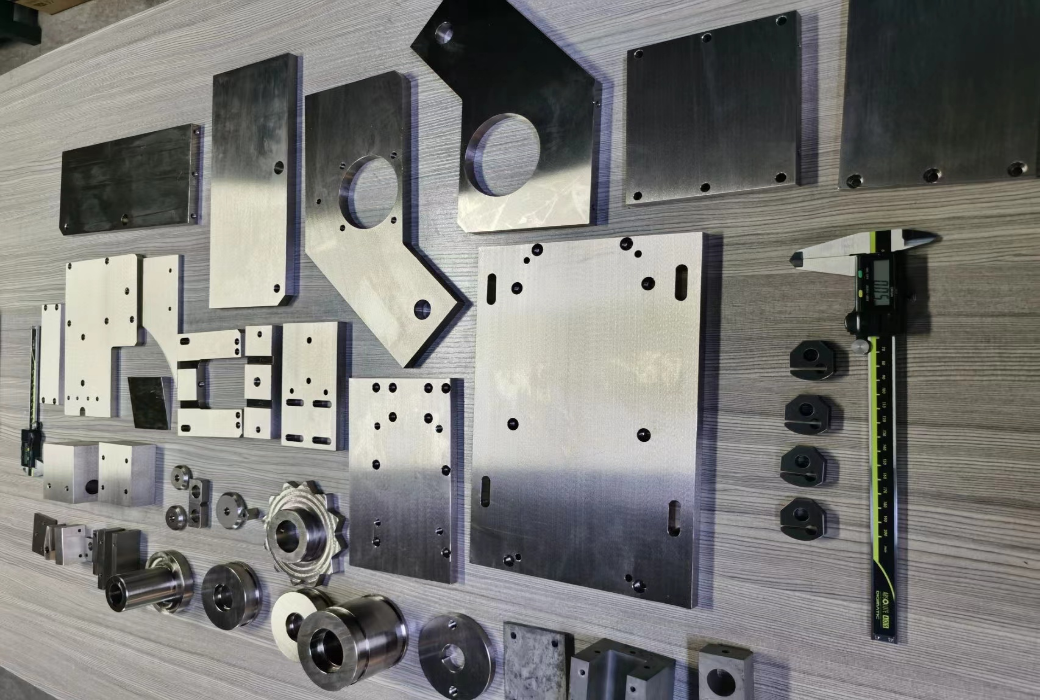

Metal and resin material SS400 / S45C / SKD材 / あなたの資料 / Aluminum material / SKS材 / SCM / SPCC / SPHC / 欲しい素材 / HPM材質 / Carbide / Brass / Copper, PVC / Acrylic / POM / MC Nylon / Bake / Peak

工場生産能力

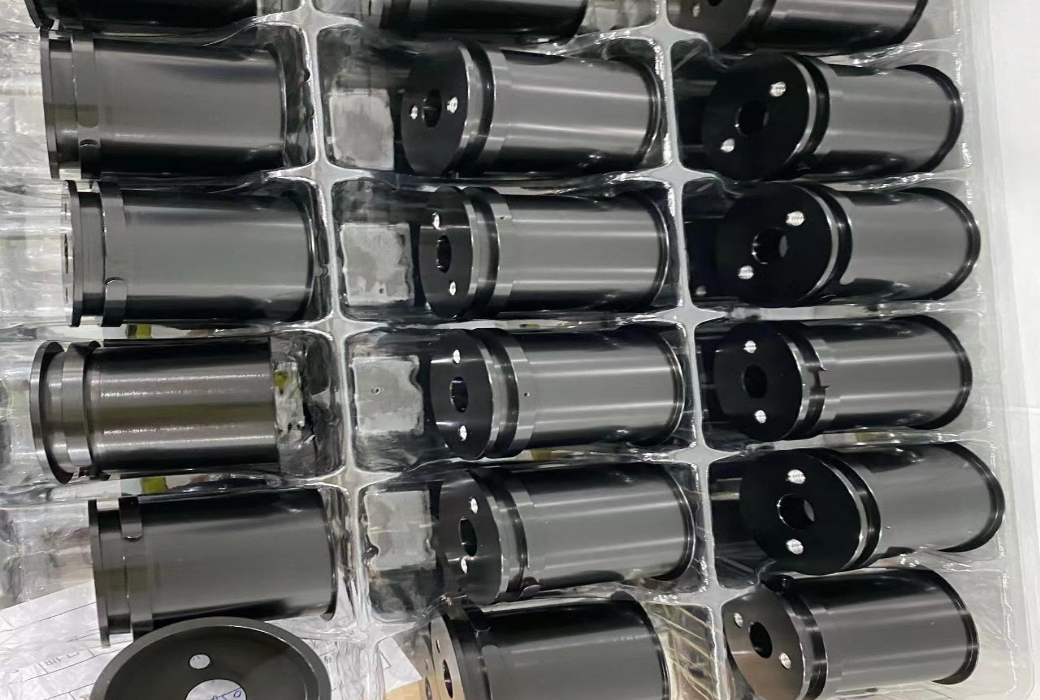

* FA automation parts, equipment-related parts, semiconductor device-related parts, accuracy ± 0.01 mm.

* Car-related parts, iron, ステンレス鋼, 真鍮, aluminum alloy, 等. are available.* Ability to process 1000 毎月絵を描く.

適用表面処理

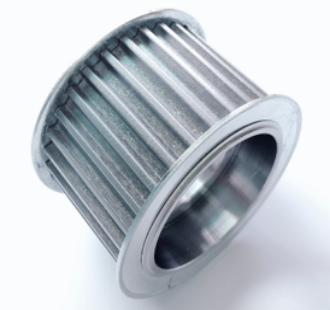

Applicable heat treatment: 真空焼入れ / 高周波焼入れ / 全体焼入れ / 浸炭焼入れ / タフトライド / 浸炭窒化 / イオン窒化 / チタンコーティング, 等.

適用表面処理: Hard chrome plating / electroless nickel plating / unichrome plating / 黒染め / raident / colored zinc plating / various alumite etc.

Manufacturing team/

容量

parts processing,旋盤加工,以上で 18 years of experience in machining masters, we can provide good mechanical design and better parts processing solutions to help customers reduce production costs. A full understanding of all customer product requirements, combined with CR’s uncompromising production standards, are the key basic factors for all successful projects.We uphold an attitude of humility to learn, keep making progress, provide customers with high-quality services, and strive to become customers’ global partners.

In the field of precision parts manufacturing, we have achieved very good cooperative relations with customers in the United States, Europe and Japan, and have also accumulated rich experience in the manufacture of auto parts, semiconductor parts and FA automation parts.

私たちのサービス : ■ Car parts■ 3C Parts■ FA Parts■ Fluid parts■ Medical parts■ Semiconductor device■ ISO& JIS standards■ 5M quality control■ CPK quality control

Metal processing Parts

見せる

自動車部品

3Cパーツ

FA部品

私たちについての人々の意見

私たちのクライアントから

貴社のサービス姿勢, 応答速度, 品質保証, 配送もすべて非常に満足しています.

Alethea購買部

金型の流動解析は非常に詳細です. 金型製造工程中, 制作の進捗状況は毎週共有されます, これはプロジェクトのフォローアップに非常に役立ちます. どうもありがとうございます.

Kevinツーリングプロジェクトディレクター

最近, 購入した自動車部品のバッチには本格的な CPK 管理が必要です. 多くのサプライヤーを見つけました, しかし校正は失敗しました. 御社を見つけて初めてこの製品が量産化にこぎ着けました.

マスク自動車エンジン製造部

お見積り依頼や詳しいご相談をご希望の方へ, お問い合わせフォームをご利用ください.

精密部品や機械自動化用金型の研究開発・製造を行うメーカー, 半導体, 自動車, 医療機器.

製品&サービス

会社について

ニュース&テクノロジー

- 技術的な案内

- ニュース&展示会

お問い合わせ

- +86 0769-81667180

黄

黄 セールス01

セールス01

営業部長

営業部長