Categories

- News (43)

As the medical industry continues to grow and advance, plastic injection molding plays a vital role in making sure that medical equipment, devices, and consumables meet exacting standards of precision, quality assurance, reliability and safety. Access to cutting-edge technology such as advanced robotic arms for automation and high-resolution finishing processes while maintaining cost competitiveness is an ever-growing challenge for medical manufacturers. This blog post will dive deep into how innovative solutions leveraging plastic injection molding technology can help address industry challenges by improving stability over time while offering competitive advantages in terms of accuracy and capability to manage complexity.

Lean Manufacturing in Medical Molding: Efficiency and Waste Reduction

In the world of medical molding, efficiency and waste reduction are not just buzzwords, but critical components of success. That’s where lean manufacturing comes in. By focusing on eliminating waste and increasing efficiency, lean manufacturing principles can help medical molding companies create high-quality products while streamlining their operations. From minimizing inventory to optimizing production processes, there are endless ways to put lean manufacturing to work in the medical molding industry. Not only does this approach help businesses save money, but it also helps ensure that patients receive the best possible care. So, if you’re interested in improving your medical molding operations, it’s time to start exploring the benefits of lean manufacturing.

Complex Geometries: Meeting the Challenges of Intricate Medical Components

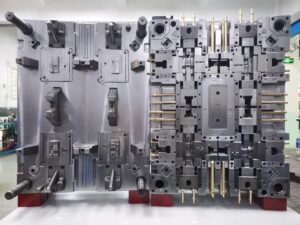

The intricate designs of medical components have led to a growing demand for manufacturing processes that can handle complex geometries. From custom implants for bone repair to intricate instruments for delicate surgeries, traditional manufacturing methods simply can’t keep up with the demands of the medical industry. This is where complex geometries come in. They allow for the production of highly specialized medical components that are tailored to individual patients, resulting in improved patient outcomes and reduced recovery times. With the growing importance of complex geometries in medical manufacturing, it’s clear that the future of the industry lies in innovative solutions that can meet the unique challenges of this rapidly evolving field.

Biocompatible Molding: Ensuring Safety in Implantable Devices

As technology continues to advance, so does the development of implantable devices. Biocompatible molding is a crucial aspect of ensuring the safety of these devices. This process involves using materials that are compatible with the human body, preventing any adverse reactions or complications. With the rise in demand for implantable devices, it has become increasingly important to carefully consider the materials and molding techniques used to create them. Biocompatible molding not only ensures the safety of patients but also increases the lifespan of the implant. By using the latest advancements in biocompatible materials and molding techniques, we can continue to improve the safety and effectiveness of implantable devices.

Medical molding is an ever-evolving industry that requires strategic planning and innovative materials to deliver solutions that are safe, effective, and reliable. By utilizing lean manufacturing strategies, medical molders can achieve greater efficiency and waste reduction while still producing intricate geometries. Additionally, they can ensure the safety of implantable devices through the use of biocompatible materials. Creating medical components requires careful consideration in terms of design, material selection, assembly techniques, and workflow. It’s necessary to consult experts at every step of the process to ensure a successful outcome on a satisfactory timeline. If you are considering medical molding for a project or need help identifying cost-saving solutions, contact our experts today to learn more about how they can assist you in taking your product from concept to reality!