Categories

- News (43)

Introduction:

In the ever-evolving landscape of modern manufacturing, sheet metal processing stands at the forefront of innovation. Its seamless integration with automated technology has revolutionized the automatic industry, enhancing efficiency, precision, and product quality. This article delves into the pivotal role of sheet metal processing in the automatic industry, highlighting its impact on production processes and technological advancements.

Precision and Efficiency in Sheet Metal Processing:

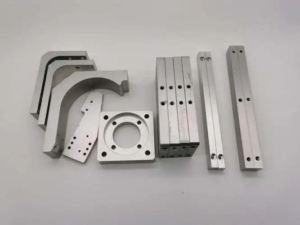

Sheet metal processing, characterized by its versatility and precision, has become a cornerstone of the automatic industry. With the aid of advanced machinery and automation, intricate designs and complex shapes can be crafted with unparalleled accuracy. The seamless bending, cutting, and forming of metal sheets not only ensure precision but also optimize production efficiency, allowing for rapid, high-volume manufacturing.

Automated Systems Transforming the Industry:

The integration of sheet metal processing with automated systems has ushered in a new era for the automatic industry. Automated machinery, guided by sophisticated algorithms and robotics, can handle various metals and thicknesses, adapting swiftly to changing requirements. This transformative synergy enables manufacturers to meet stringent deadlines and deliver products of exceptional quality, positioning them as industry leaders.

Innovation and Technological Advancements:

Sheet metal processing within the automatic industry is marked by continuous innovation. Cutting-edge software solutions enable precise modeling and simulation, minimizing material wastage and maximizing efficiency. Furthermore, the integration of automation has paved the way for real-time monitoring and quality control, ensuring that every product adheres to the highest standards. These technological advancements drive the industry forward, propelling it into a future defined by smart manufacturing practices.

Environmental Sustainability and Cost-Efficiency:

The marriage of sheet metal processing and automation not only enhances production capabilities but also contributes to environmental sustainability. By optimizing material usage and minimizing waste, manufacturers can reduce their ecological footprint. Additionally, automated processes streamline workflows, leading to reduced operational costs, enabling companies to offer competitive pricing without compromising on quality.

Conclusion:

Sheet metal processing, coupled with automation, is revolutionizing the automatic industry, driving it towards a future characterized by efficiency, precision, and sustainability. As technology continues to advance, the synergy between sheet metal processing and automation will undoubtedly lead to further innovations, shaping the landscape of modern manufacturing. Manufacturers embracing these advancements are not only improving their production processes but also setting new standards for the industry, solidifying their position as pioneers in the automatic industry’s ongoing evolution.

Driven by outstanding quality, Super Ingenuity Hongkong Co.,Ltd uphold our commitment to customer trust, leading the way with efficiency and innovation. We don’t just provide products; we offer a reliable promise and a trustworthy partnership. In our service, quality is our pride, customer trust is our driving force, and efficient operation is our hallmark. Choosing us means choosing the support of exceptional quality, opting for a dependable partner, and embracing a future that is more efficient and competitive.

Welcome to contact with us and we will off sincere services!