Super-ingenuity [HK]

東莞市超鋭精密科技有限公司

+86 0769-81667180

24/7 Customer Support

☆ Connecting the world with a Chinese town factory

[email protected]

We can respond to inquiries at any time

☆ Strive to become a partner of your company

Weixin

Linkedin

Skype

Facebook-f

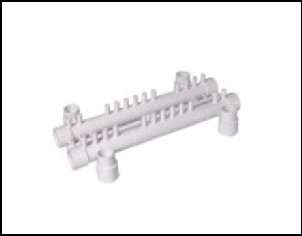

Plastic mold

Services

Mold design

Available materials

Factory capacity

Applicable surface treatment

Available materials

Development and design of molds made of various plastics such as ABS / PC / PP / PE / PMMA / PA / PA + GF / TPU / TPE / PVC.

Factory capacity

Monthly 25 ~ 30 sets Mold production capacity: Mainly plastic mold development, design and manufacturing, prototyping, mass production.

1) Test mold, mass production mold, plastic molding.

2) Mold-related: Automobiles, home appliances, packaging, medical-related molds.

Applicable surface treatment

1) Mold: Buffing, highlighting, etching

2) Plastic products: Secondary processing, plating processing. Automobiles, home appliances, packaging, medical-related molds.

Plastic molding

Available materials

Factory capacity

Applicable surface treatment

Available materials

ABS / PC / PP / PE / PMMA / PA / PA + GF Poly / TPU / TPE / PVC.

Factory capacity

Compatible with single color molding, two color molding, metal parts insert molding, and 10 plastic molding machines.

Applicable surface treatment

Secondary processing, plating processing. Automobiles, home appliances, packaging, medical-related molds. machines.

Mold parts processing

Available materials

Factory capacity

Applicable surface treatment

Available materials

1) Japanese JIS material: SS400 / S45C / SKD material / SUS material / SKS material / SCM / SPCC / SPHC / NAK material / HPM material /

2) Imported materials from Europe and the United States: H-13 / S-7 / 420SS Stavax / 1.2344 (1.2343) /1.2379/1.2378/1.2510/P20, etc.

Other special materials: brass, pure copper, titanium alloy, beryllium material.

Factory capacity

1) Precision mold parts processing up to ± 0.005.

2) Monthly 1000 drawing processing capacity.

3) We are good at processing plastic dies, connector dies, and press dies.

Applicable surface treatment

Vacuum quenching / induction hardening / whole quenching / carburizing quenching / tuftride / carburizing nitriding / ion nitriding / titanium coating, hard chrome plating / vacuum hard chrome plating / DLC coating treatment / black dyeing / mirror buffing, etc.

3) We are good at processing plastic molds, connector molds, and press molds.

Design Team/

Capacity

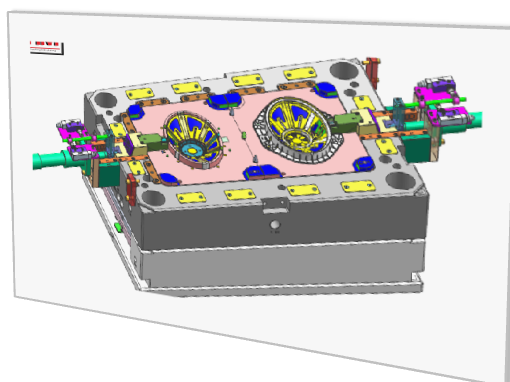

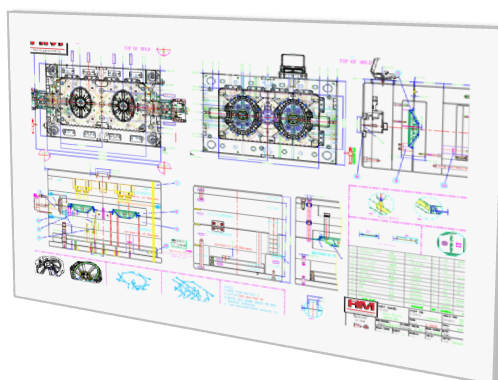

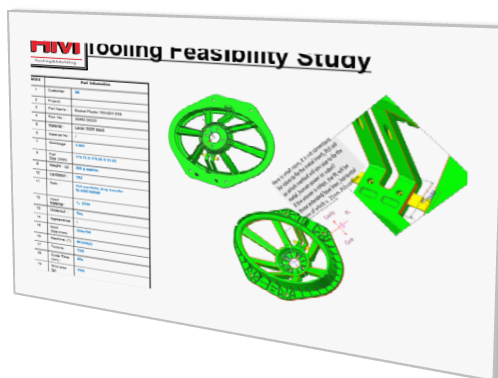

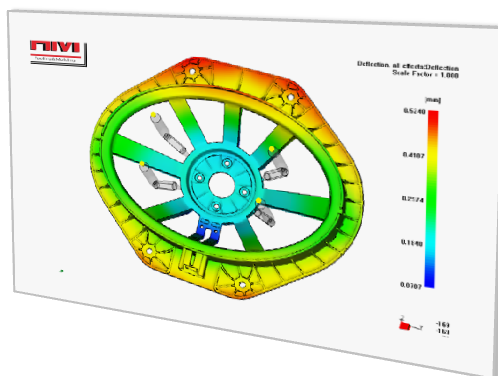

With more than 15 years experience designer, we can provide well tooling design and better part analysis solution to help customer decrease tooling cost. a full understanding of all customer product requirements, combined with CR’s uncompromising design standards, are the key foundation factors for all successful tooling programs.

Our Services : ■ DFM■ Mold flow analysis■ Product optimization■ Full 2D & 3D mold design■ Mold design optimization■ Reverse engineering■ Collaborative design with customer’s idea

Project

Management

Project manager has rich experience in tooling designing, tooling making and machining and project managing, also has a good ability of coordinating, planning, Japanese and English communicating. Project manager is a main contact window to customer, and provides good customer experience from project begin to finish. Our work process is designed to keep the customer informed and get control of his project throughout the process. Below shows clearly how the customer supervise his project in 4 stages efficiently.

Previous

Next

Plastic Parts

show

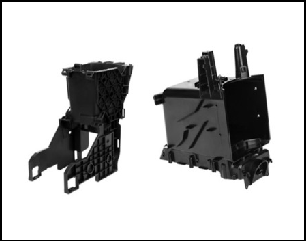

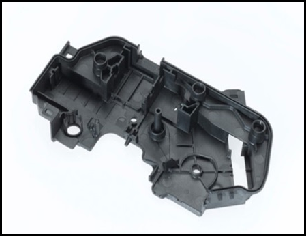

Automotive molded part

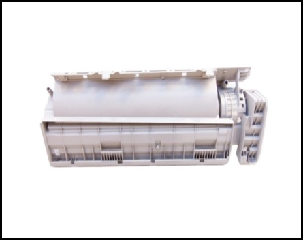

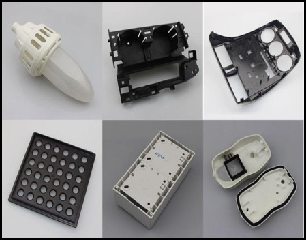

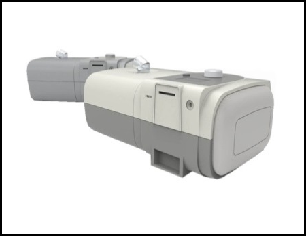

Electronics Household Appliance & Other Molded Part

Medical parts & Other Molded Part

What People Say About Us

from our Client

Your company’s service attitude, response speed, quality assurance, and delivery are all very satisfied.

AletheaPurchasing Department

The mold flow analysis of the mold is very detailed. During the mold manufacturing process, the production progress will be shared in time every week, which is very helpful to our project follow-up. thank you very much.

KevinDirector of Tooling Project

Recently, a batch of auto parts purchased requires full-scale CPK control. We have found many suppliers, but the proofing has been unsuccessful. It was not until we found your company that this product finally achieved mass production.

MuskAutomobile Engine Production Department

If you would like to request a quote or have a detailed consultation, please use the inquiry form.

A manufacturer engaged in research and development and manufacturing of precision parts and molds for machine automation, semiconductors, automobiles, and medical equipment.

product &Service

About Company

News & Technology

- Technical Information

- News & Exhibition

Contact us

- +86 0769-81667180

Huang

Huang Sales01

Sales01

Sales Manager

Sales Manager